What is FAB LAB?

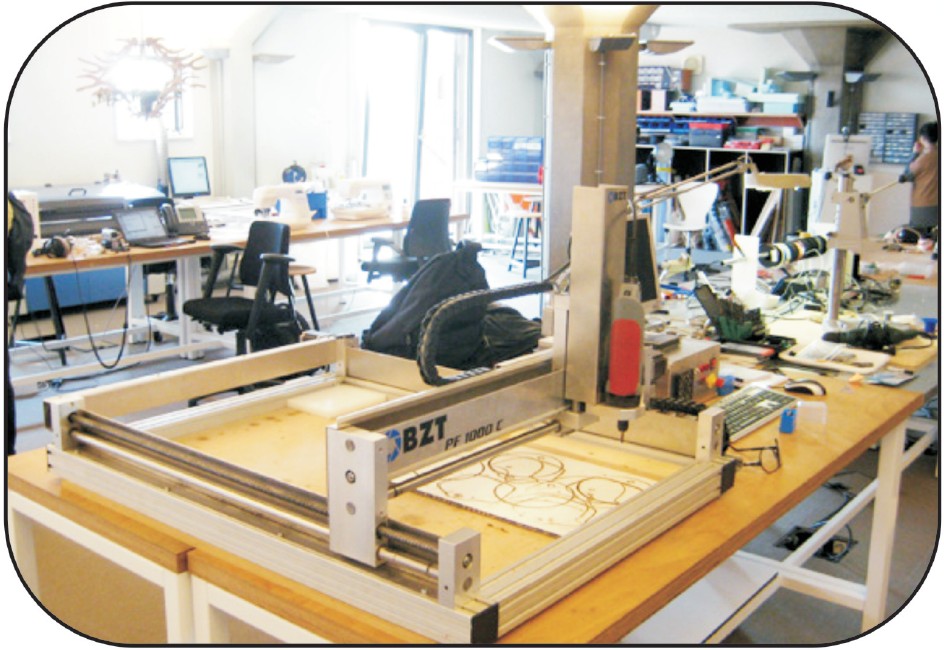

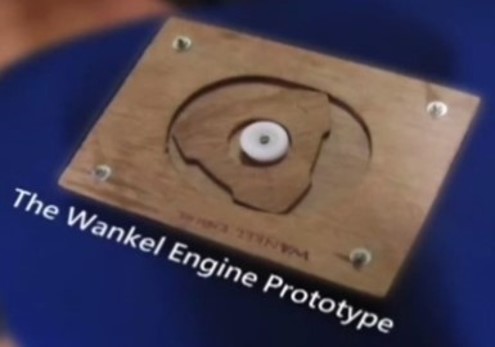

Fab lab is a Digital Fabrication facility with set of machines and software for directly converting CAD designs to physical parts. The idea of Fablab was conceptualized in the Centre for Bits and Atoms (CBA) group at MIT. MIT is recommending every Engineering Institution to have a Fab Lab facility as this will be great tool to foster innovation.

More details about fab labs and fab lab foundation can be found at these websites:

Advantages of FAB Lab to College & Students:

- Complete digital fabrication facility (convert designs into physical prototypes & models)

- Useful for fabricating prototypes for student, academic & research projects.

- Useful for all Engineering departments in the college.

- Can be used for curriculum training of various courses like CAD/CAM lab, mechatronics lab, metrology lab etc.

- Get recognised by MIT in their website and become part of a global network of recognised fab labs.

- Offer vocational and manufacturing skill development training programmes to students & professionals.

- Offer consultancy services on digital fabrication to Industries.

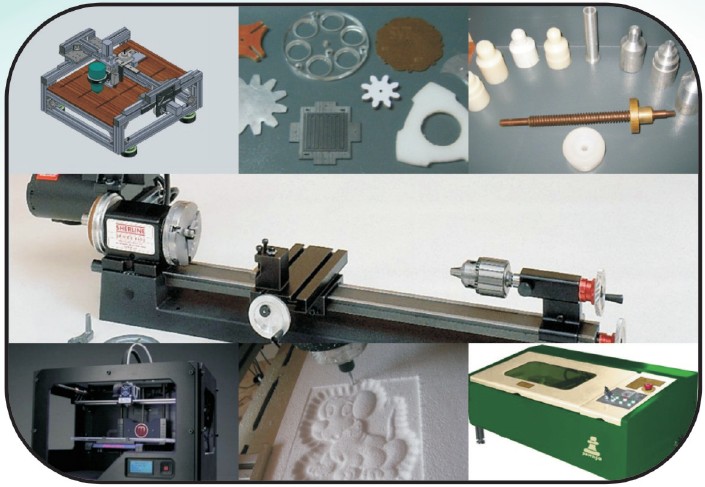

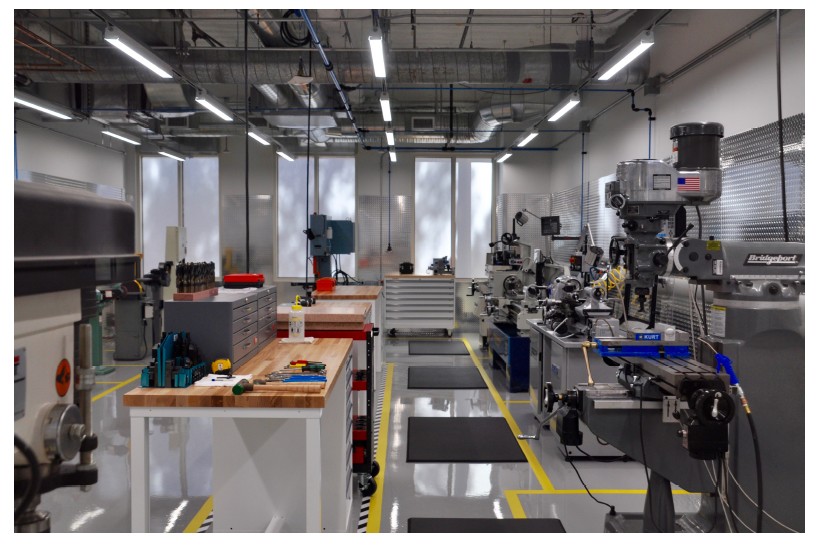

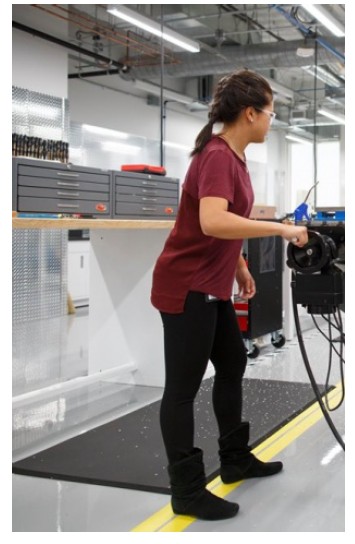

Equipments in Fab Lab:

Basic : Laser, Router, Lathe, 3D Printer, PLC Controller kit for Automation

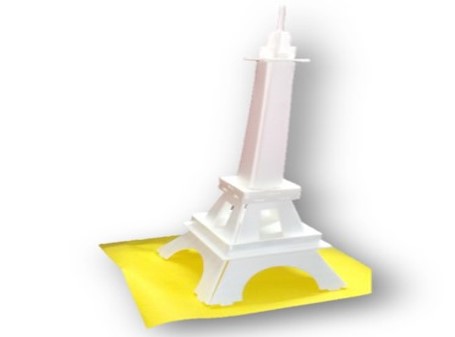

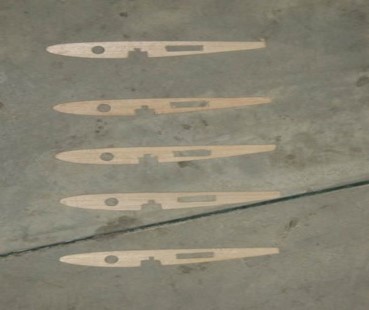

- A computer controlled laser cutter , for press-fit assembly of 3D structures from 2D parts.

- A larger numerically controlled milling machine, for making furniture – (and house-) sized parts

- Rapid prototyper : typically a 3D printer of plastic or plaster parts.

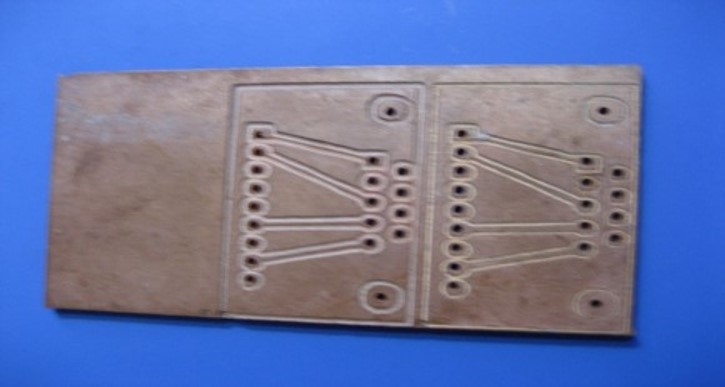

- A precision (micron resolution) milling machine to make three – dimensional molds and surface mount circuit boards

- A sign cutter , to produce printing masks, flexible circuits , and antennas

- Programming tools for low cost high speed embedded processors

Advanced Set of Equipments:

- CNC gas and Plasma Cutting Machine

- CNC Milling Machine

- CNC Lathe

- CMM

- Vision guided robotics etc.

How it is useful for various Engineering Departments:

Students and researcher and faculties of all engineering departments like :

- Mechanical Deaprtment

- Electrical/Eletronics Department

- Civil / Architecture Department

- Aerospace Department

- Metallurgy Department

can benefit from this fab lab facitlity.

Mechanical Department: Fabricate various mechanical components like gears, CAM profiles, sprockets, robot chassis, mechanims etc.

Electrical/Electronics Department: Fabricate PCBs, Circuits, Motor Mount Plates etc

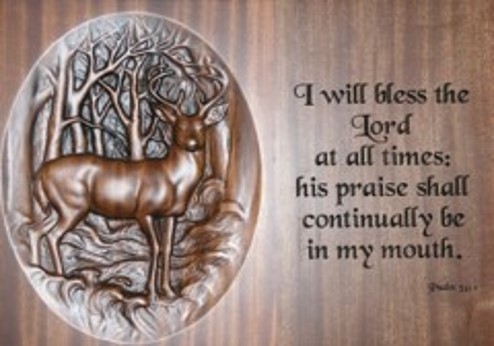

Civil / Architecture Department: Architectural Models, Patterns in Wood, thermocol etc

Aerospace Department: Aero Modelling parts in Balsa Wood, FRP Material , Foam, Thermocol etc

Metallurgy Department: Casting Patterns in Wood, Thermocol , Machinable Wax etc

News and Events:

Several CORPORATES and educational institutes are setting up Fablab/ Hardware innovation lab to aid in faster product development, innovation, KAIZEN etc..

In Colleges: Fablabs go a long way in helping students to pratice ” LEARNING BY DOING “.

You can refer to following links for projects ideas:

Obama tours MIT-developed trailer containing digital fabrication, design, and manufacturing tools:

http://news.mit.edu/2014/mits-mobile-fab-lab-at-white-house-maker-faire-0620

Europeon Corporates combine Fablab:

Facebook’s Fablab Area404:

Harvard University Graduate School of Design’s Fablab:

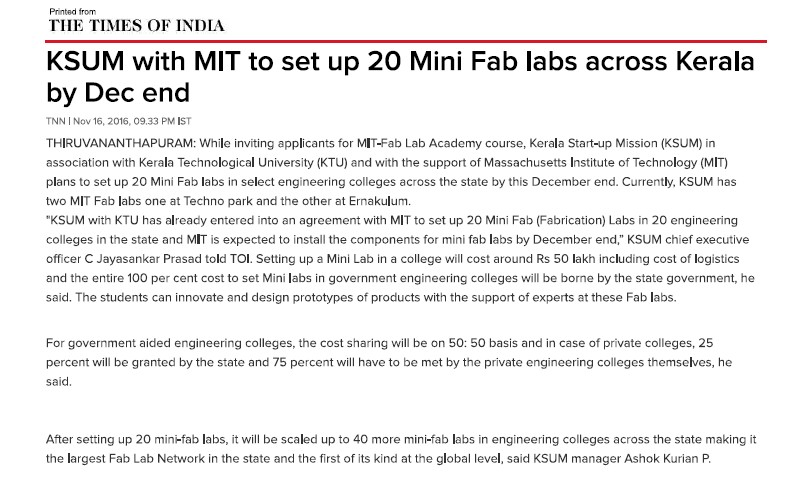

KSUM With MIT to set up 20 Mini FabLabs across Kerala

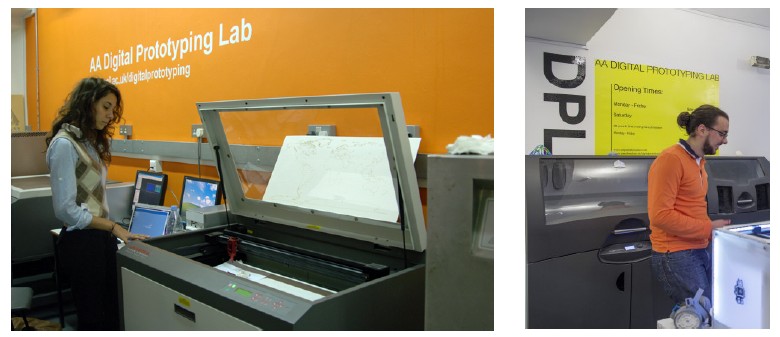

Fab lab setup in Architectual Association, School of Architecture, London, UK :

The Digital Prototyping Lab is a model making facility, manufacturing laboratory and digital fabrication knowledge hub within the Architectural Association School of Architecture.

It is equipped with several 3D printing technologies (SLA, SLS, FFF), 3-axis CNC milling machines, laser cutters, 3D scanning and industrial robotic arms. It is available to all current students and staff, and enables access to the most current CAD-CAM technologies for individual projects or specialist courses.

Fab lab setup in School of Architecture and Built Environment(SABE), The University of ADELAIDE Australia :

https://blogs.adelaide.edu.au/architecture/2013/05/07/model-making-laboratory/

SCHOOL OF ARCHITECTURE AND BUILT ENVIRONMENT (SABE)

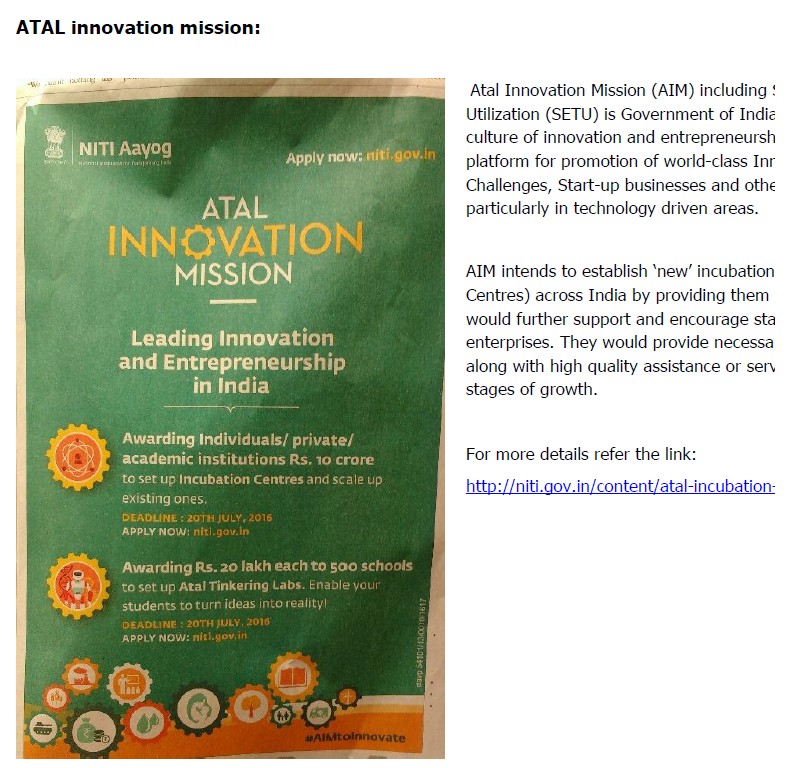

ATAL innovation mission:

Atal Innovation Mission (AIM) including Self-Employment and Talent Utilization (SETU) is Government of India’s endeavour to promote a culture of innovation and entrepreneurship. Its objective is to serve as a platform for promotion of world-class Innovation Hubs, Grand Challenges, Start-up businesses and other self-employment activities, particularly in technology driven areas.

AIM intends to establish ‘new’ incubation centres (Atal Incubation Centres) across India by providing them with financial support. AICs would further support and encourage start-ups to become successful enterprises. They would provide necessary and adequate infrastructure along with high quality assistance or services to start-ups in their early stages of growth.

For more details refer the link:

All India Council for Technical Education (AICTE) will set up ‘tinkering labs’ across institutes. TOI dt 24.11.2019